Under the International Energy Agency’s sustainable development scenario, cement producers will need to reduce their carbon intensity at an annual rate of 0.3% per tonne of cement produced up to 2030 [ii]. With carbon emission regulations tightening globally to meet the 2-degree scenario (2DS) targets, cement companies that fail to adopt low.. cement industry in general. Figure 1 depicts the five competitive forces t hat shape the global ce ment industry. Ri valry is moderate, the effect of substitutes is weak, buyer power is minimal.

Creative Use of Cement Outside of Construction in Agriculture to Art

Industrial Security supporting digitalization in the cement industry

Is Iranian Cement threat to Pakistani Cement Industry ? Shaikh

(PDF) Cement Industry Final DOKUMEN.TIPS

Infographic The Embodied Carbon in Global Steel and Cement Trade

Import Cement from China, Cement Supplier and Factory in China

A Solid Grip in the Cement Sector

Cement substitution by a recycled cement paste fine Role of the

(PDF) A Study on the Impact of COVID19 Pandemic on the Financial

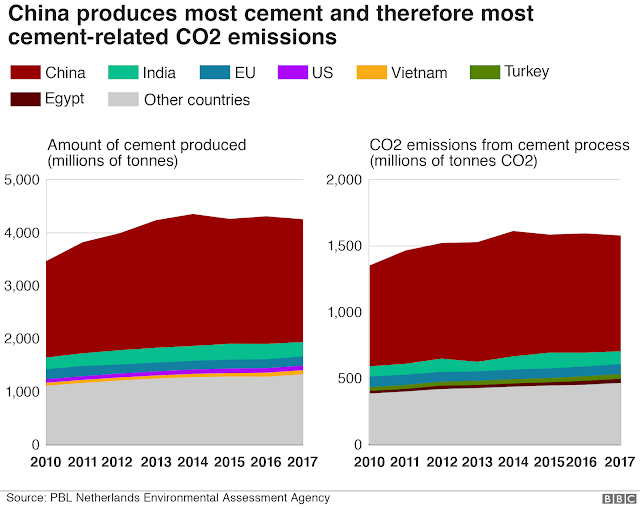

Arjunpuri in Qatar The massive CO2 emitter you may not know about

Cement industry

4 QFD for the cement industry Download Scientific Diagram

(PDF) “Financial appraisal of cement industry in IndiaA comparative

15 Types of Cement and Their Use Cases

The cement industry at a turning point A path toward value creation

(PDF) OCCUPATIONAL HEALTH AND SAFETY IN CEMENT INDUSTRY

3 Trends Impacting the 3.9 Billion Metric Ton Global Cement Industry

Research & development of the cement industry

HWI Refractories Products/Applications for Cement Industry

Making the cement industry climateneutral via carbon capture and

Achieving an average global clinker ratio of 0.60 by 2050, as set out in the 2018 Technology Roadmap, would require roughly 2 billion tonnes of clinker substitutes to be consumed in 2050, 215 almost 40 per cent more than the quantity consumed today. 216 At the same time, the global availability of traditional clinker substitutes – fly ash and.. Kartini et al. [56] performed a study to evaluate RHA as a cement substitute for producing green concrete. In. experimental analyses, six replacement ratios as 0%, 10%, 20%, 3 0%, 40% and 50% were.